| |

1) Serial Port MODBUS ASCII & RTU: Master and Slave All F-series, M-series and Nano-10 Super PLCs feature at least one or more serial ports (RS232 and/or RS485) that speak both MODBUS ASCII and RTU protocols fluently! These super PLCs can work happily with many other third party MODBUS masters or slave devices or with other super PLCs, thereby providing an open system solution. It is ready to interface to vast majority of other industrial software and hardware. 2) TCP/IP MODBUS: MODBUS/TCP Server and Client F-series and Nano-10 Super PLCs' built-in Ethernet port also support the industry standard MODBUS/TCP protocol which is widely used by SCADA software and Touch Panel HMI that has Ethernet. This allow the PLCs to be remotely monitored via the Internet using Modbus/TCP protocol protected via trusted IP, or through the native protocol with username and password protection. In addition, F-series and Nano-10 PLC can also make a client connection to any device that has a MODBUS/TCP server built-in so that the PLC can remotely retrieve data from remote sensor or data acquisition system.

|

The Super PLC's Dual Independent MODBUS Ports

Back to the top

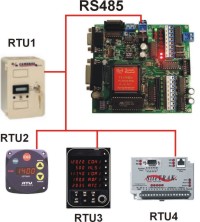

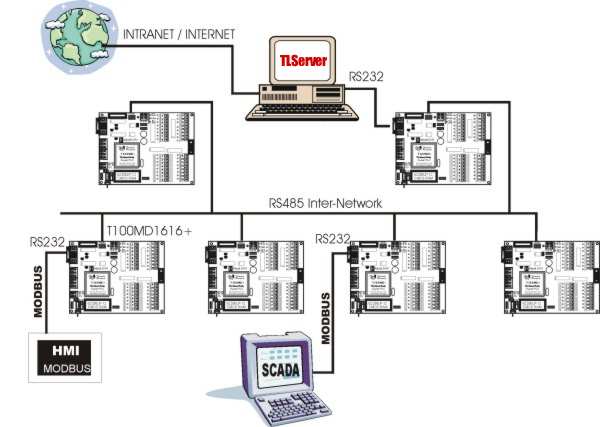

Amazingly, even the lowest cost T100MD888+ super PLC comes with two independent UARTs for its two serial ports: COMM1 is an RS232 port and COMM3 is an RS485 port. Both comm ports support MODBUS ASCII and RTU and can run simultaneously! The built-in RS485 port means networking a number of super PLCs will cost you extra $0.00 - (except maybe only for the price of the twisted pair cable). You can therefore connect as many as 32 super PLCs to a SCADA host very cost effectively. By replacing the standard RS485 driver with 1/4 or 1/8 power type (e.g. Linear Technology LTC1487) as many as 256 PLCs can be networked together and pay next to nothing!

Another possible application is to use the RS485 for inter-networking between the PLCs so that data can be shared between the PLCs. You can use the MODBUS protocol or the native protocol to accomplish this networking function. Hence you can have a network of super PLCs in a big system (such as building automation control) networked together by the RS485 , at the same time each PLC node can talk to other MODBUS host or slave devices using its RS232 port. No other PLCs in the market today can rival the vast communication flexibility of the M-series super PLCs regardless of their price! This makes the T100MD1616+ an ideal choice for all applications from standalone machine controller to large systems employing hundreds of PLCs

![]()

© Copyright 2012 Triangle Research International, Inc

All Rights Reserved