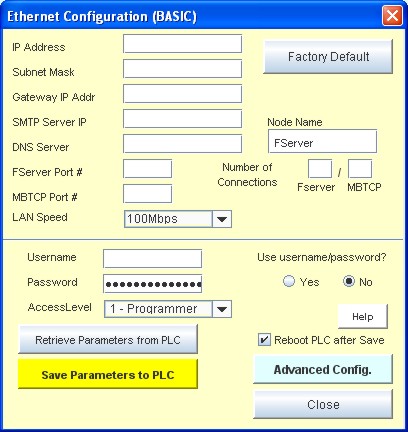

All commands in this menu are for communication with the PLCs via the

PLC Ethernet F-Server or via the TLServer. Hence either the PLC's Ethernet port is

connected to the LAN, or a TLServer software must be actively running and connected

to the PLC(s) via the PC's serial port before the commands here can be successfully

executed.

If you are using the TLServer software, then note that TLServer can be

running on the same computer that i-TRiLOGI is running on (using localhost IP 127.0.0.1) ,

or on another computer in the same local area network, or anywhere in the world with an

Internet connection. The experience is identical regardless of where the TLServer (and

hence the PLC) is situated.

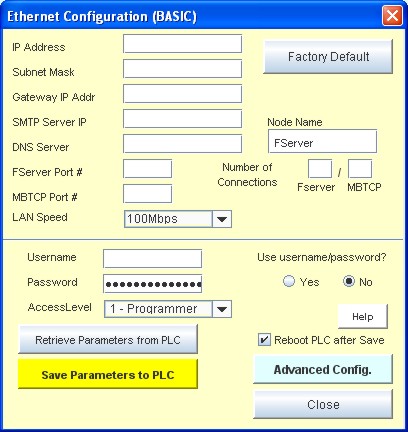

If there is no existing connection made to the F-server or the

TLServer, then execution of any command in this menu will always bring up the password

dialog for you to enter the Username/Password as well as the IP Address:port of the

server. If you have enabled the "use password" option in the F-Server or if you

are connecting via TLServer, then you must be positively authenticated before you are able

to log-in to the server. See Log In to TLServer for detailed

explanation of the Username/Password Dialog box. Once you have log-in to the server, see

explanation of each function below:

The only editable field is the ID field. You have to enter the ID

address in hexadecimal notation (00 to FF). This command allows you to select another PLC

that is connected to the same TLServer but with a different ID for on-line monitoring or

program transfer.

Use this command to log-in to the PLC Server or

TLServer only if you have no intention to perform other controller commands. You may find

that you seldom need to use this command since running the On-Line Monitoring or Program

Transfer commands will also let you log-in to the TLServer if you have not yet done so.

However, once you are connected, this command changes into "Disconnect from

Server" and this is the way for you to log out of the currently connected PLC so that

you can use the Username/Password dialog box to log-in to another PLC of a different IP

Address/port number.

See On-Line Monitoring help page for details.

This command is only available if your log-in username is assigned the

access level of a "Programmer". If you log-in as a "User" or

"Visitor", this command is disabled from the Controller's menu. (It will be

enabled again after you disconnect from the server)

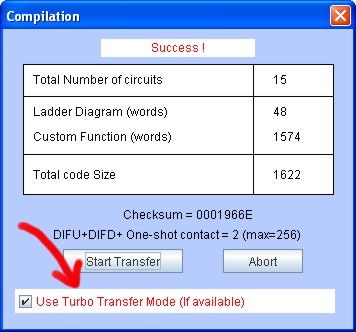

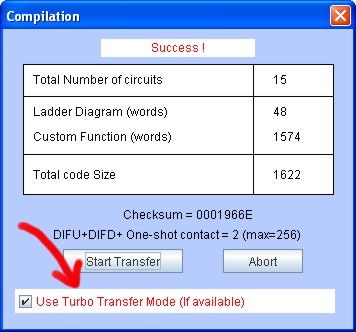

You can use this command to transfer your i-TRILOGI ladder+TBASIC

program into the PLC. You will be prompted to confirm your action to prevent accidentally

affecting the target PLC. The ladder program must be compiled successfully before the

program transfer process can take place. The progress of the transfer process will be

clearly shown on the program transfer dialog box.

NOTE:

When performing a program transfer, it is possible to abort a

transfer even after the transfer has started. However, the PLC will be left in PAUSE state

if a program transfer has been aborted to prevent execution of an incomplete program. So

the user must re-transfer the correct program for the PLC to work.

TL7 now supports a default "Turbo

Transfer" mode, which uses binary FTP protocol to upload the code

image to the PLC instead of via ASCII command strings. Turbo Transfer can greatly reduce

the program transfer time for very long PC7 program. This can greatly enhance programmer's

productivity during program development when small changes to the program happen very

frequently.

However, in order for Turbo Transfer mode to work, it requires that the

PLC's FTP server to be accessible in active mode from i-TRiLOGI. Normally this is not an

issue when the PC and the PLC are on the same local area network. However, in the case

where the PLC is sitting behind a NAT firewall where only port 9080 is mapped, a user

using i-TRiLOGI to remotely program the PLC via the Internet will notice that the PC

running i-TRiLOGI may not be able to access the FTP server port (21) on the PLC, and

therefore the Turbo Transfer mode will fail. When this happens I-TRiLOGI automatically

switches back to regular transfer mode using ASCII string to transfer the codes one block

at a time via port 9080. The user can also selectively disable Turbo Transfer mode to

reduce the time wasted in trying for Turbo Transfer mode that could not be performed.

Turbo transfer de-selection is volatile. When TL7 is re-started Turbo Transfer Mode will

be selected by default.

This new command is added from i-TRiLOGI version 6.41 onwards. It lets you transfer a

file that has been saved previously to the hard disk using the "File -> Write

Compiled Code To Disk" function under the "File"

Menu.

Using this function you can send compiled code to other users to be transferred into

the PLC using a licensed copy of i-TRiLOGI v6.41 and above, but without revealing your

source code. To ensure that the file is not corrupted when you email to others, try to

compress it using a Zip or Rar software.

You can use this command to query the connected PLC for the filename of

the last i-TRiLOGI program transferred to it and it will attempt to match it to a file

stored in the log-in user's directory at TLServer or on the PC's hard disk. If the file is

found, it will be opened. Otherwise it will report that the file is not found. Note that

this command only opens the source file based on file name matching. It does not verify

whether the file has been modified. It is the user's responsibility to ensure that the

file stored in the server is the same one that has been compiled and transferred to the

PLC.

If you have created a new file (i.e. the file name is

"Untitled" ) and then attempt to perform on-line monitoring, this command will

be called automatically to try to open a file that matches the PLC. The command is also

invoked when you select a PLC with a different ID either from the "Controller"

menu or from within the "Full-Screen Monitoring" window.

Note to Unicode users: If you created your file name using Unicode

instead of plain ASCII, the Unicode filename will not be saved into the F-Series /

M-series PLC since the PLCs do not support Unicode in its internal memory. In such case

you cannot use this command to open the matching source file. You would have use the

"File -> Open (Local Drive)" command to manually open the file for

monitoring purpose.

You can find out the PLC's firmware version number, the maximum of input,

outputs, relays, timers and counters supported on this PLC as well as the total amount of

program memory available. The same info will be displayed when you try to transfer a

program to the PLC.

The PLC's real time clock (RTC, which includes both date and time) can

be set quickly using this command. When you execute this command, a dialog box which

contains the year, month, day, hour, min, sec and day of week are displayed for you to

enter the value. The dialog box is initially filled with value taken from the client's

computer's own calendar and clock. You can change any of the field to the desired values

and then click on the "Set PLC's Clock" button:

The dialog box will be closed after the i-TRiLOGI has transferred all

the data to the PLC. You should use on-line monitoring to verify that the data has indeed

been properly written into the PLC.

Note that the "Year" field is restricted to only between 1996

and 2096, "Month" is between 1 and 12, "Day" is between 1 and 31,

"Hour" is between 0 and 23, "Min" and "Sec" are

between 0 and 59. If you enter an illegal value i-TRiLOGI will beep and the cursor will be

put at the offending text field. Correct the mistake and then click on the "Set PLC's

Clock" button again to transfer the values to the PLC.

This new command is added since i-TRiLOGI version 6.47 build 01.

It can force the PLC to reboot as if it has been powered cycle so that it can load new

configuration or clear any system errors. This command however does not work on the

older T100MD+/T100MX+ PLCs.

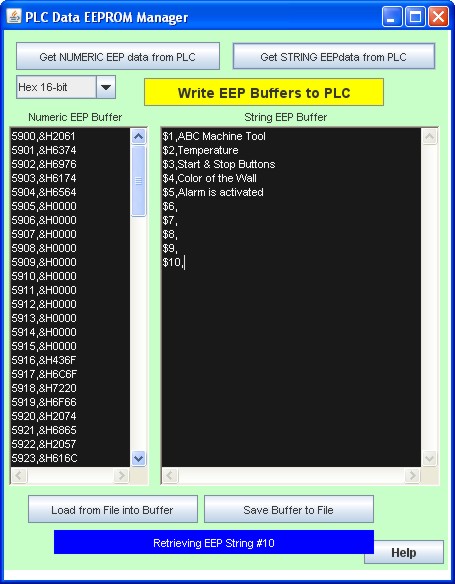

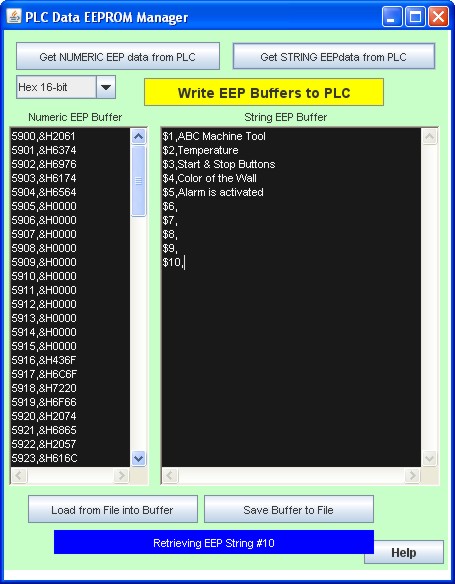

This new command is added starting from i-TRiLOGI version 6.1. Please click here for more details

This new command is added starting from

i-TRiLOGI version 6.3. Please click here for more details

This new command is added starting from

i-TRiLOGI version 6.43. Please click here for more details